My

custom apparel journey

from 2004 to current

Here is a brief history of my shirt experience.

I have been paddling a dragon boat since 1993. At that time everyone always wore cotton. Know one knew that there was anything better. In the early 2000, teams started to wear polyester uniforms. At that time they were pretty expensive. In 2006 I started my own team and figured I would find someone that could make my shirts for me. Boy was that a pain. Everyone would do screen printing, on either cotton or polyester blanks. With the cost going up dramatically with each color added to the design.

After several years of toying with screen printing I found a printer that would dye-sublimate a jersey for me in 2014. I had lots of problems with those jerseys. Then I found another printer in 2015. Again a different set of problems arose. I went back to screen printing for two years.

Then in 2017 I decided that I will find a printer that will give me what I want, but more importantly needed. I will be in complete control of the process. Which of course also has its own headaches and costs. But it was a learning process and I was very, very happy with the outcome.

2019 we used previous jerseys.

Then covid happened in 2020 so no races to go to. No new designs either.

2021 and 2022 I had found a new printer that had the “Holy Grail” of fabrics. Lightweight, wicking and snag resistance. They have held my hand figuring out what works and what doesn’t in the industry. I am most grateful for their guidance. So there you go, my history of me getting my jerseys made.

—

2004

Cotton Screen Printing. We were in Victoria B.C. When we paddled we got wet. it took forever for the shirts to dry.

—

2006

First screen printing, 2 color on generic polyester. Fairly comfortable.

—

2007

First screen printing 2 color on Nike dri-fit. SUPER Expensive and thier logo was not placed well.

—

2009

Screen printing 2 color on ALO POLYESTER. COMFORTABLE, BUT EXPENSIVE.

—

2010

Sprayed water soluble Screen Printing Ink. BADGER POLYESTER SHIRTS. SO SO FOR COMFORT. BUT THEY WERE FAIRLY INEXPENSIVE.

—

2012

Screen printed 2 color on Gildan polyester. somewhat confortable. Wanted a v-neck, but only had v-necks for women.

—

2013

First 4 color screen printing on Gildan polyester. Again, Not the softest material.

—

2014

First dye-sublimated shirt from China. Several things wrong with this shirt. First was the sizing. We were sausages in these. Second was the color. The left shirt is the reprinted shirt. The “O” in Fusion at the top should be PMS Cyan color. The NorAm should have been in color also. When the reprint was done, the fonts were still wrong.

“—

2015

Second dye-sublimation from China. Same company that another major race uses. Was not told several things before we ordered them. Two main issues. Hugely large. Like two sizes too large. and I ordered Red, Not Construction Orange. Then next year the sales man called ame and said “oh yeah we have had womens shirts for years.”

—

2016

Back to 2 color screen printing BAdger polyester. Team Fusion’s 10th year paddling. I redid the original design with our updated logo. V-necks only for womens agian.

—

2017

Slightly different 2 color screen print on BAdger polyester.

—

2018

My shirt pattern and design. Dye-sublimated in Pacific North West. Athletic fit shirt. Plus I got a v-neck finally for the men.

—

2022

Full Dye-Sublimated Designed and printed in the U.S.A. Made unissex for everyone.

—

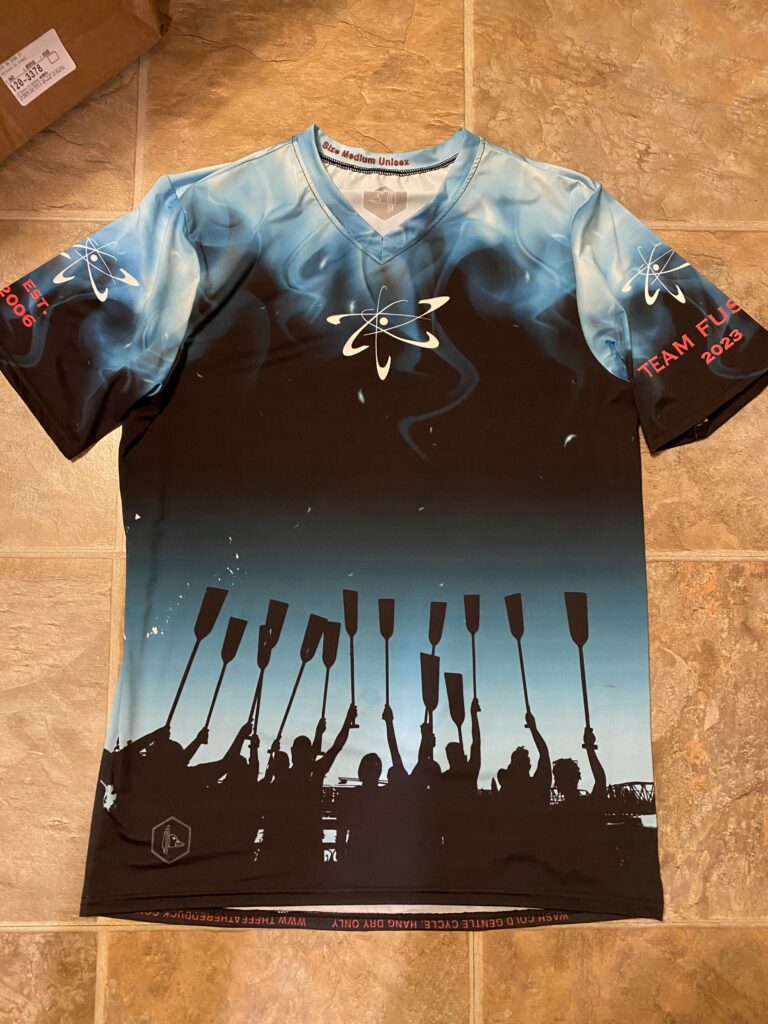

2023

Team Fusion’s general shirt. This one had banding on it. The other runs did not. Like the other two color ones below.

—

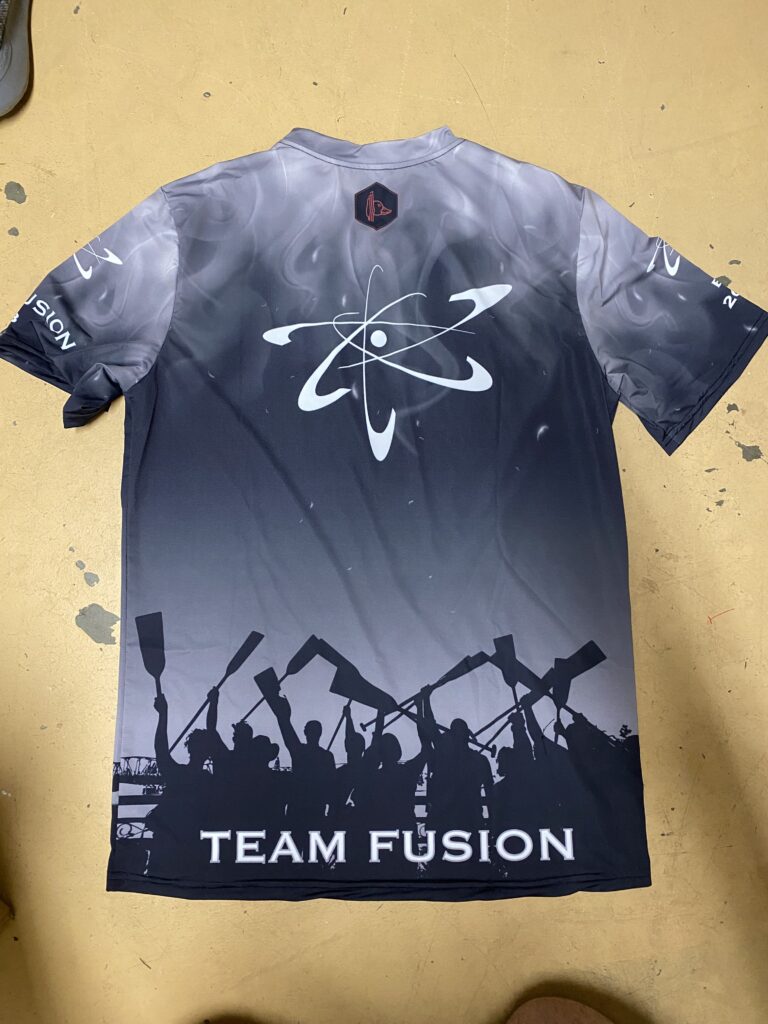

2023 Custom Jersey

The head coach wanted a GreyScale one.

—

2023 Team Fusion “Red” Womens Boat

The womens boat wanted a red shirt as we name the boats by color instead of another name.